EFFICIENCY

- M5 Two Spoke: the new standard for time trial and triathlon

- Used even by Dutch Olympic Tandem Teams in RIO 2016 ( 1 x silver, 1 x bronze) proved their unique lateral and radial stiffness!

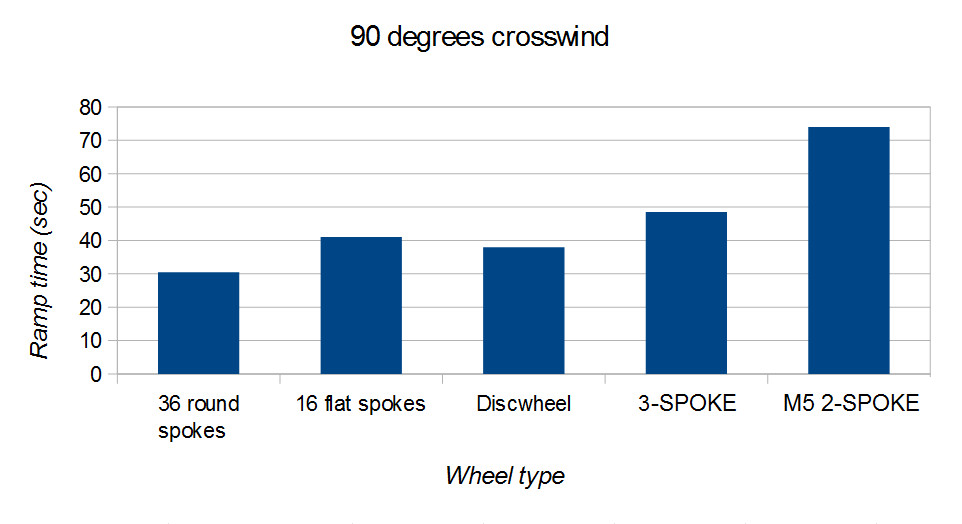

- The “M5 Two Spoke” has the LOWEST air resistance of ALL existing wheels compared to 12 or 16 steel bladed spokes or 3, 4, 5, or 6 carbon bladed wheels and even DISC wheels! This means the “M5 Two Spoke” is currently the fastest wheel in the world.

- The aero-dynamical properties of the two-spoke wheel were extensively examined with Computational Fluid Dynamics (CFD) by analysing the wheel’s performance at different angles of attack of the passing air.

- Studying the CFD files confirmed that the much smaller and aerodynamic surface area takes the credit for this thrilling accomplishment! We already knew, of course, that using a disc wheel above a wind-speed of 3 m/s is already slowing you down a lot because of bigger exposed frontal area, but defeating a disc wheel “in its own habitat” in the velodrome is truly sensational!

- It all boils down to the air resistance of the spokes of any wheel. One wants to transfer steering, braking and driving forces whilst minimally disturbing the air. Since one mostly rides forward, this means minimal drag, with side wind you might have some lift effects. Assuming the same roughness and other conditions, the drag depends on the shape and the wetted area, normally it is assumed the disc is best on shape, but worst on wetted area. The 2, 3, 4, 5, 6 or 16 spokes have normally lower wetted areas, but also less aerodynamic shapes, which means that often the disc was better despite the high wetted area. Now we have achieved a trade off that makes it better than a disc, i.e. we gained performance relative to the disc due to wetted area, more than we lose from the shape. It might seem complicated, but we know what really matters! And thus, the two-spoke wheel with optimal aero-dynamical properties is now a reality.

- In other words, by using two spokes instead of three or five, which are the most popular right now, the M5 Two Spoke wheel has less “wet area” then the aforementioned. It also performs better in side winds due to the same surface area left and right of the steering line. This is normal practice for the even bladed four or six spoked carbon wheels too, by the way.

- All this is clearly proven by recent and independent SRM tests by AeroPro and CFD tests.

- The current design is distinctive from it’s predecessor of 1987 by using a wider (23.7 mm) rim section and modified NACA 0018 spoke section profiles. Also, the height of the rim increases from 48 to 90 mm where the wings meet the rim. In this area the wing tips flow into a higher rim section in order to get best aerodynamics.

- The benefits of this wheel in a one hour time trial compared to a standard carbon 3-spoke wheel can be as much as 2.5 minutes (!) when averaging 51 km/h.

- Supreme radial and lateral stiffness thanks to internal sections and the use of Toray 1000. Wheels have been used even by the Dutch Olympic Tandems in RIO 2016 resulting in a silver and a gold medal. Remember that doubling the load leads to 8 times bigger! forces and they have proven they can handle this.

- UCI approved design

- From idea to product

It was about time to set a new standard after almost 25 years of domination of other type of wheels… The invention of this wheel dates back to 1987! By that time M5 founder Bram Moens completed the first version of it. This was done years before carbon three-spoke wheels were introduced. And already in 1985 Derk Thijs (www.rowingbike.com) and Bram made their first own designed and very lightweight carbon disc wheels . So, why did it take that long to introduce a serial version? The main focus at M5 was designing and building special frames, (record)bikes, lightweight bicycle parts, and streamline bodies for special bikes. Also at that time, serial manufacturing in carbon wasn’t as developed as nowadays.

For the 3D design of the 2-SPOKE wheel Bram worked together with Bob Vroegh from the company “Vroegh Design”.